VoltAero's parallel electric-hybrid powertrain has begun certification testing for the five seat Cassio 330 aircraft.

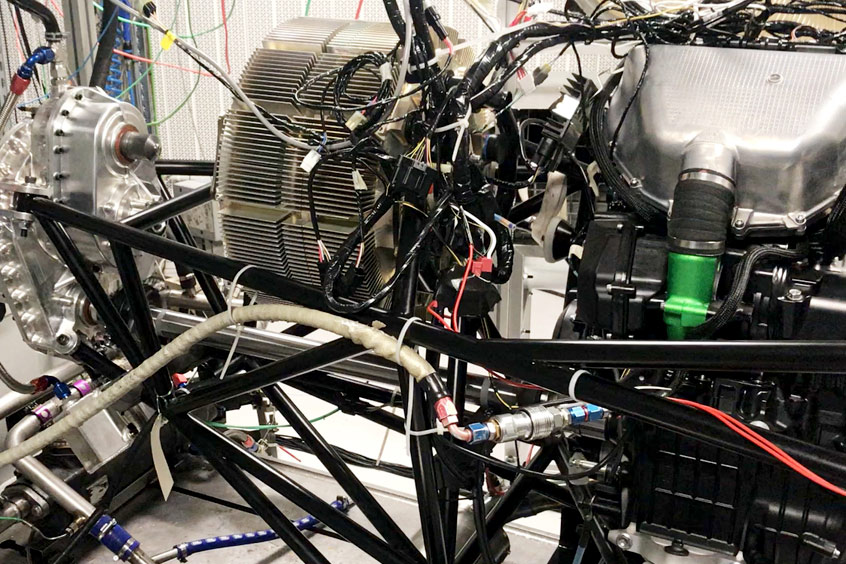

Installed on a ground-based test bench, this powertrain integrates the key elements for series production Cassio 330s: Safran Electrical & Power's ENGINeUS 100 smart electric motor and Kawasaki's four cylinder, high-performance thermal engine derived from the iconic Ninja motorcycle.

The Cassio 330's powertrain has a combined electric-hybrid power of 330 kilowatts, with 180 kilowatts delivered by the ENGINeUS 100 electric motor and 150 kilowatts provided by the Kawasaki thermal engine.

"Full-scale powertrain certification testing for our Cassio 330 marks another important step in VoltAero's commitment to produce a new-generation electric-hybrid aircraft family, bringing together our proprietary powertrain with an airframe that is optimised for aerodynamic and operational efficiency," says CEO and chief technology officer Jean Botti.

The ground-based test bench runs of Cassio 330's powertrain are underway at the Bayonne, France facility of AKIRA Technologies.

Botti adds that VoltAero's overall architecture for the Cassio 330 powertrain already has been validated during extensive flight testing with the company's Cassio S testbed aircraft, which is equipped with a powertrain version rated at 600 kilowatts - the most powerful electric-hybrid system of its type flying today. Cassio S has performed more than 230 flights since October 2020, surpassing the combined 170 flight-hour mark while covering 15,000 kilometres and visiting 40 plus airports.

The VoltAero parallel electric-hybrid propulsion concept for Cassio is unique, with the aircraft using the electric motor in its aft fuselage-mounted propulsion unit for all-electric power during taxi, take off, primary flight (if the distance travelled is less than 150km) and landing. The hybrid feature - with the internal combustion engine integrated in the powertrain - comes into play as a range extender, recharging the batteries while in flight. Additionally, this hybrid element serves as a backup in the event of a problem with the electric propulsion, ensuring true fail-safe functionality.

By integrating VoltAero's parallel electric-hybrid propulsion system into the company's purpose-designed airframe, Cassio will deliver an order of magnitude higher performance as compared to the current competition, and provide significantly lower operational costs.

VoltAero's first production aircraft version will be the Cassio 330, for which the company has targeted certification in late 2025. It will be followed by the six seat Cassio 480 with a combined electric-hybrid propulsion power of 480 kilowatts, and the Cassio 600 - sized at a 10/12-seat capacity with electric-hybrid propulsion power of 600 kilowatts.

VoltAero's headquarters and technical offices are currently located at Médis, France. A purpose-built facility incorporating the final assembly line for Cassio aircraft is under construction at Rochefort and is to be inaugurated later this year.