Why visit ACE ’25?

ZeroAvia will be offering some of its key components designed for its hydrogen-electric engines to other clean aviation innovators. The move allows ZeroAvia to build upon the multi-billion dollar per annum market for its hydrogen-electric powertrain family, maximising its investment in R&D and its strategy of vertical integration, as well as furthering its impact on reducing environmental harm from aviation.

With the certification work for the ZA600 engine for up to 20 seat aircraft underway, and the underpinning technology for the ZA2000 engine for up to 90 seat aircraft in advanced development, ZeroAvia has conducted component market research and sees significant opportunity in the following areas:

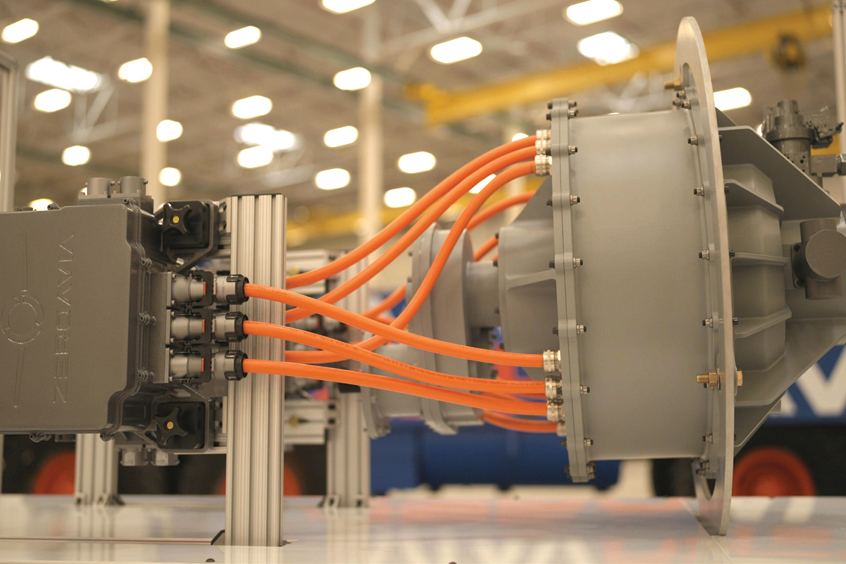

- Advanced electric motors for aviation, including a 660kW max-power direct-drive motor capable of speeds up to 2,200rpm, and the HyperCore 900kW modular motor capable of speeds up to 20,000rpm.

- Silicon carbide inverters - The 200kW continuous power bidirectional inverter design offers a power density above 20 kW/kg and is available in single (225kW peak/200kW continuous) and dual (450kW peak/400kW continuous) configurations. The inverters are designed and produced following aerospace standards, allowing a high-power density and reduced weight with advanced thermal management technologies and integration to enable reliable high performance for high altitude and engine compartment location.

- Low temperature Proton Exchange Membrane (LT-PEM) fuel cell configurations (in partnership with PowerCell) – ZeroAvia’s SuperStack Flex architecture is a customisable 100-400kW fuel cell power generation platform designed to meet a range of different aerospace power, performance and packaging requirements while maintaining exceptional pressure, mass flow rate, humidity and temperature control.

- High temperature PEM (HT-PEM) fuel cell stacks and full power generation systems - ZeroAvia’s High-Temperature Proton Exchange Membrane (HTPEM) fuel cell stack is a turbo-air cooled modular system which offers up to 3.5kW/kg specific power, supporting a variety of traditional aviation and VTOL applications.

- Aviation fuel cell compressor is a leading-edge compressor capable of supporting up to 900kW fuel cell applications up to 15,000ft. The compressor is designed specifically for fuel cell applications and designed for aerospace standards from the start.

The company is in active discussions on potential deals with a number of companies working on electric and hydrogen aviation innovations.

To facilitate the production of the electric propulsion systems (specifically, power electronics and electric motors) for both its own powertrains and its component offering, ZeroAvia is opening its propulsion center of excellence at Paine Field in Everett, north of Seattle. At a ribbon-cutting ceremony, guests got a glimpse of how the new facility will support manufacture of the electric propulsion systems in the new 136sq ft facility. It also houses existing R&D operations. ZeroAvia also plans a separate facility focused on producing hydrogen fuel cell systems – a Hydrogen Center of Excellence - and is currently exploring site selection.

Val Miftakhov, founder and CEO, says: "We are setting forth plans that detail how we are going to bring our engines to market for commercial aircraft as well as the additional market potential in components generated by our pursuit of aerospace applicable fuel cell and electric propulsion technologies.

“We intend to secure as much market share for commercial aviation propulsion systems as possible as this will enhance shareholder value and ensure we deliver in tackling climate impact in the sector. While the market for our powertrains is thousands of engines across commercial aircraft, there will be other applications that are not strategically aligned with our full engine offering, but where our technologies can play a major role in the supply chain for other OEMs. And with the opening of the new facility, we are also able to show ZeroAvia’s growth from ambitious startup into a clean aerospace manufacturing powerhouse, with a production site officially opened in Everett. The future is bright for clean flight, Washington State."