Why visit ACE ’25?

Engine Assurance Program (EAP), the hourly maintenance programme for operators of Honeywell, General Electric, Rolls-Royce and Pratt & Whitney engines, has agreed to send 20 TFE731 engines to Duncan Aviation for MPI, CZI and unscheduled events over the next 12 months.

EAP's hourly engine maintenance programme covers scheduled and unscheduled maintenance, including life-limited parts, LRUs, R&R, shipping, rentals, line maintenance, trend monitoring and catastrophic coverage while boasting a 99.99 per cent dispatch reliability rate. EAP supports all variants of the TFE731 engine and their APUs, which power many of today's most popular business jets.

“EAP and Duncan Aviation have worked closely for several years, and we have had four engines through Duncan Aviation's shop in the last 30 days for scheduled and unscheduled events. This partnership is providing great results for clients, so we have agreed to send Duncan Aviation 20 TFE731 engines over the next 12 months for their respective shop visits,” says EAP programme coordinator Sean Lynch.

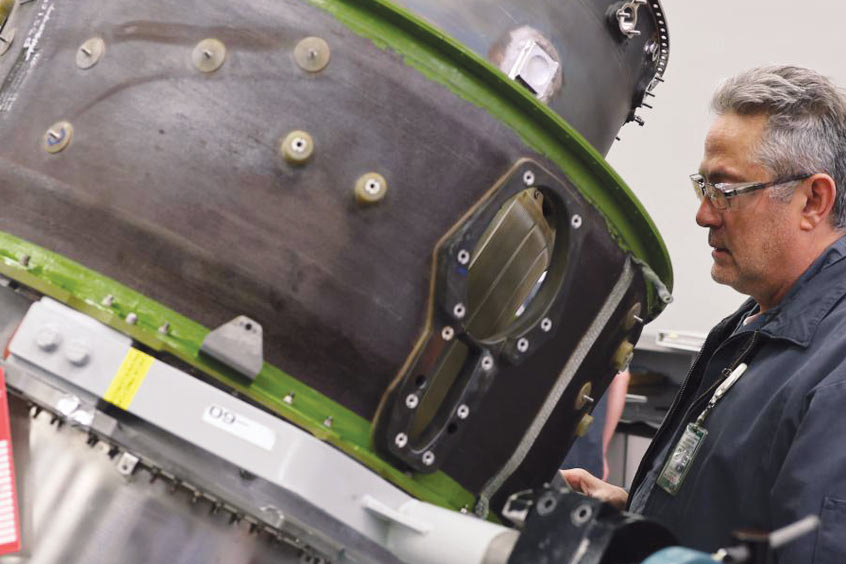

Duncan Aviation is a Honeywell-authorised TFE731 line/major/heavy level service provider with a Honeywell certified 20,000 lb thrust-class turbofan engine test cell and control room housed in a modern 20,000 sq ft turbine engine facility in Lincoln, Nebraska.

“Our relationship with EAP has grown organically over the years. This has greatly benefited both companies as well as aircraft owners. Over that timeframe, we have developed a good understanding of EAP's company values and how well they align with our own values. As a Honeywell-authorised facility we utilise parts authorised or provided through the OEM. This is the same quality expectation that EAP has for its customers,” says Duncan Aviation VP of sales Ryan Huss.

“We're aligned both technically and culturally,” adds Lynch. “We don't just take care of engines; we take care of people. Duncan Aviation shares this same customer-centric philosophy, which is why we're excited to bring this partnership to customers. It provides the high-quality product that we expect for our clients and great service.”

In addition to dispatch reliability, EAP provides customers with increased residual value of their aircraft, enhanced customer service and meaningful cost savings.