Why visit ACE ’25?

Daher has unveiled the latest high-end version of its TBM pressurised single turboprop aircraft family, the TBM 960, which incorporates Pratt & Whitney Canada's advanced PT6E-66XT engine and a fully digital e-throttle, along with a digitally-controlled cabin that incorporates an all-new environmental control system, LED ambience lighting and electrically-dimmable windows.

“The TBM 960 is the quintessential TBM, representing the fifth evolution of our very fast turboprop aircraft family since the TBM 900 series' introduction in 2014,” says senior vice president of Daher's aircraft division Nicolas Chabbert. “It takes the maximum advantage of today's turboprop technology to provide digital control of the engine and the propeller.”

The TBM 960 retains the rapid speed of Daher's TBM family while enabling lower fuel consumption. At the recommended cruise setting of 308 kts, the fuel consumption is only 57 US gallons per hour, which is a 10 per cent fuel economy compared to the maximum cruise setting, for more sustainability.

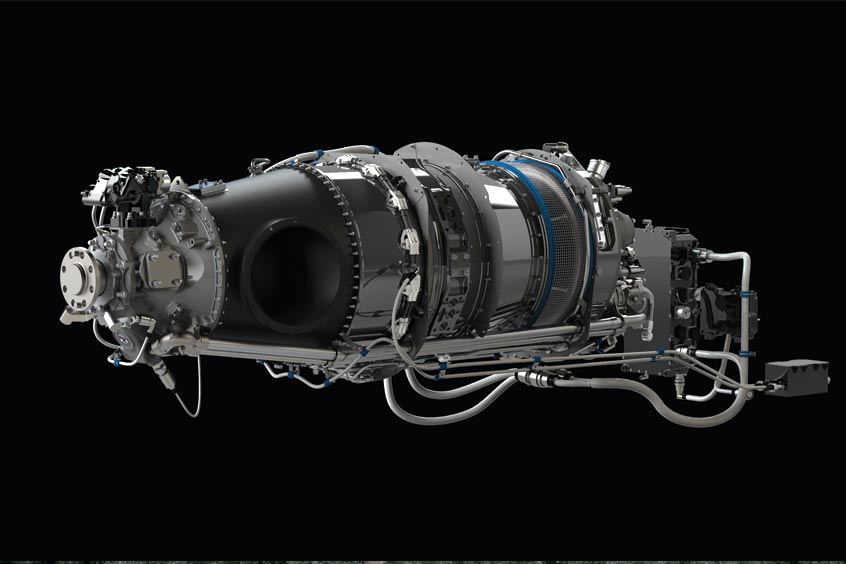

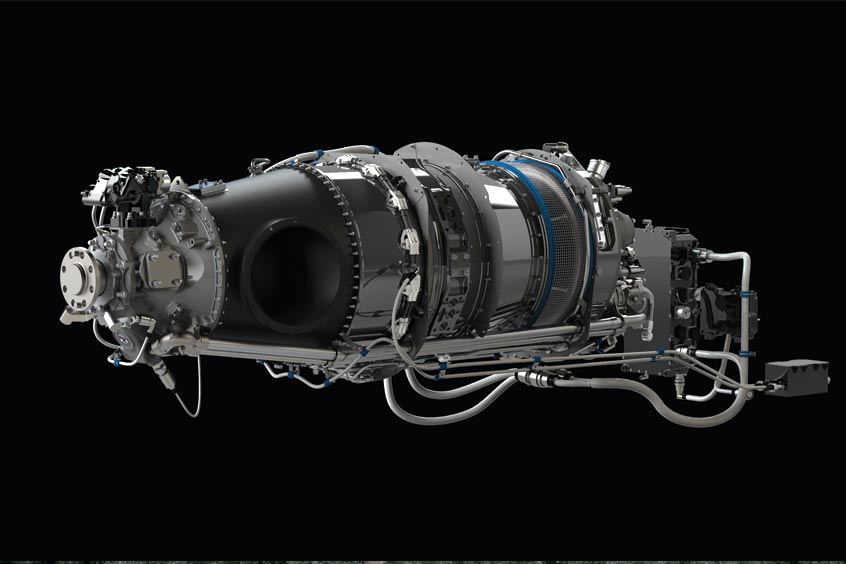

At the heart of this latest TBM version is the intelligent PT6E-66XT powerplant and Hartzell Propeller's five-blade Raptor composite propeller, both of which are linked to the dual-channel digital engine and propeller electronic control system (EPECS).

With the EPECS, the PT6E-66XT's startup is fully automated after a single-switch activation. The cockpit's power lever is an e-throttle, using a single forward position from take off to landing, with the EPECS optimising powerplant performance throughout the flight envelope while reducing pilot workload by integrating all functions and protecting the engine's life. Analysis of engine parameters is driven by 100-plus smart data inputs.

The PT6E-66XT engine is purpose built for the very fast single-engine turboprop aircraft.

“We are delighted that Daher has selected the PT6E-66XT engine to power its new TBM 960,” says P&WC vice president, general aviation Nicholas Kanellias. “The introduction of the PT6E-66XT engine reaffirms our continued commitment to innovation and our desire to proactively bring solutions to our customers. Driven by more than 100 digital data inputs, it offers the optimal combination of precision, performance and efficiency for an elevated and simplified flying experience.”

The PT6 E-series is the first engine family with a dual-channel integrated electronic propeller and engine control system in the general aviation turboprop market.

“We have worked closely with Pratt & Whitney Canada for more than 30 years in integrating PT6 turboprop engines on our TBM and Kodiak aircraft families,” adds Chabbert. “With its PT6E-66XT version, the Pratt & Whitney Canada team has taken innovation to a new level, providing digital power to our TBM 960 flagship single-engine turboprop aircraft, making it even easier to operate.”

The PT6E-66XT engine offers an enhanced and simplified pilot experience. The digitally enabled single lever simplifies engine operation and allows for true precision-controlled auto-throttle. This provides for a more intuitive way of flying, from engine start to propeller and engine control, which reduces operation and pilot workload.

The engine control system provides a consistent start every time, and constantly reviews and processes all the engine and many aircraft parameters, making fine adjustments to fuel flow and propeller blade angle to deliver optimal power and efficiency during all phases of flight.

The intelligence behind the control system uses the data to deliver precise, constant engine performance at every altitude and every temperature on each flight. Other benefits include increased engine take off and climb power (+45 SHP mechanical horsepower) and increased thermodynamic power (up to four per cent at ISA conditions).

The PT6E-66XT is also digitally connected through its data collection and transmission unit (DCTU), making full-flight engine data accessible on multiple platforms, including mobile devices. Once the aircraft lands, engine flight data can be wirelessly downloaded, providing operators and maintainers with insights into engine performance and health.

Improved design features and digital capabilities increase the availability of the aircraft. Scheduled maintenance intervals have been increased, including time between overhauls from 3,500 to 5,000 hours. The electronic control system removes hardware from the engine, resulting in a combined 40 per cent reduction in scheduled maintenance.

The TBM 960 Raptor propeller is fully integrated into the propulsion system. It is specifically designed to reduce overall weight and improve take off distance, climb and cruise speed. Turning at 1,925 rpm during maximum power output, the Raptor contributes to limiting noise and vibration. Its sound level during take off is just 76.4 decibels, meeting the most stringent international noise standards.

Its G3000 integrated flight deck can be compared to an electronic co-pilot. It includes an icing protection system, flight envelope monitoring through the electronic stability and protection (ESP) and the under-speed protection (USP) systems, the emergency descent mode (EDM) function, as well as the game-changing HomeSafe emergency autoland system.

The Garmin GWX 8000 doppler weather radar is a new addition, with advanced surveillance features such as lightning and hail prediction, turbulence detection, zero blind range for close-in returns and ground clutter suppression. The TBM 960 also is the first application of Garmin's GDL 60 next-generation data transmitter for automatic database upload and interconnection with mobile devices.

The Prestige cabin extends the use of digital power inside the aircraft, featuring an all-new environmental control system, LED ambience strip lighting integrated into both sides of the overhead ceiling panel and electronically-dimmable windows, all controlled by a passenger comfort display (PCD). Enhancements also include new ergonomically enhanced seats, USB-A and USB-C power plugs, individual cupholders and headset hangers for each occupant.

A Sirocco paint scheme has been added to the aircraft's style customisation options; a fifth design option for the TBM by French designer Alexandre Echasseriau.

The TBM 960 has been certified by EASA, with certification by the US FAA currently underway. Deliveries will begin in the first half of 2022.