Why visit ACE ’25?

Vallair, a mature aircraft asset MRO dedicated to the support of operators and lessors, has augmented its MRO capability with the introduction of in-house non-destructive testing. The capability will not only be available at Vallair's specialist MRO facility in Montpellier and the Aerostructure repair shop in Châteauroux, but also away from these locations worldwide, with both Form 1 and 8130 release available.

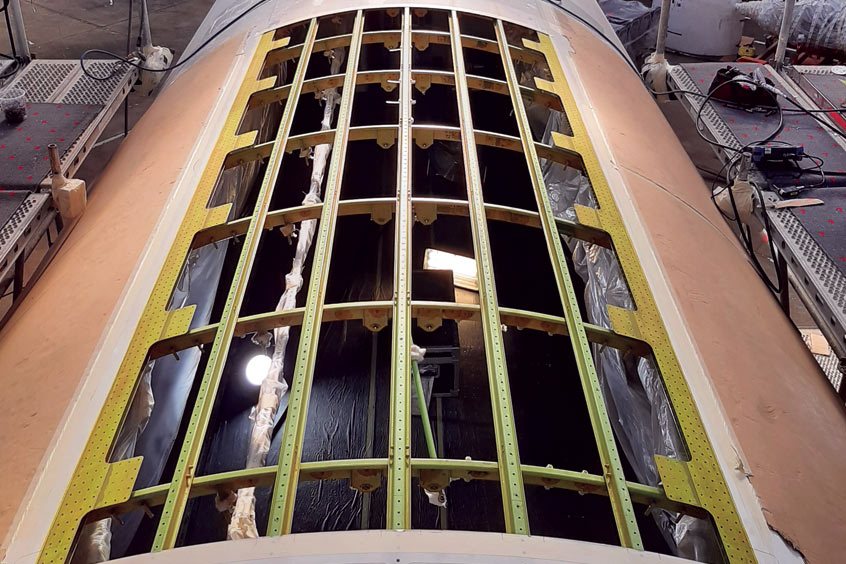

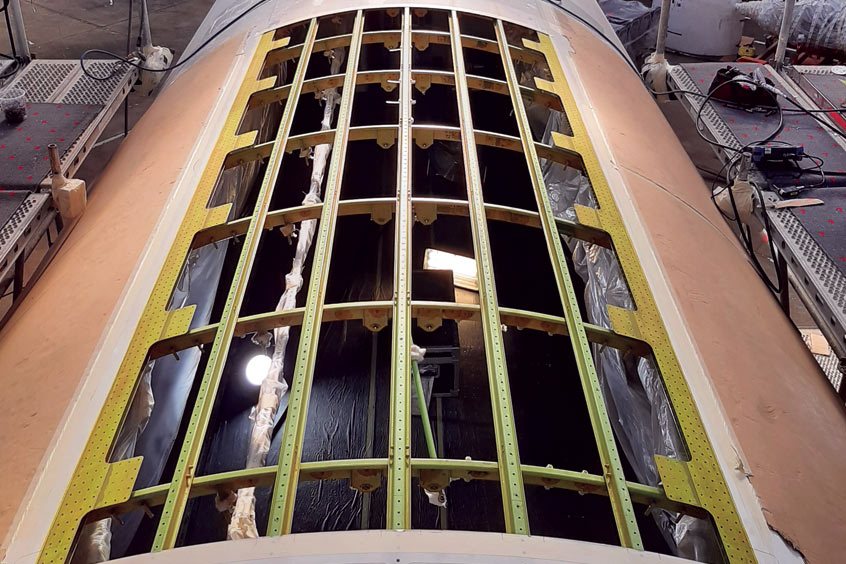

NDT techniques are necessary to determine whether an aircraft is airworthy. It is a broad category of inspection techniques, and is an important tool in aircraft MRO. NDT includes the inspection of an airframe structure and engine for surface and sub-surface cracks, impact damage, corrosion, and other irregularities. These inspections must be done without having to dismantle components therefore minimising downtime.

“Safety is the single most critical aspect of aviation. NDT is used throughout a product's lifecycle, from the qualification of new materials and the design of new aircraft to in-service inspections of aircraft structures and engines,” comments Malcolm Chandler, head of commercial and marketing for Vallair. “The introduction of NDT in Montpellier is testament to our dedication to customer service. Currently we offer comprehensive repair capability, aircraft reconfiguration, painting and cabin refurbishment, as well as parking and storage. Previously, NDT was something that would be outsourced to third parties but had become difficult due to the restrictions surrounding COVID. The addition of NDT will allow us to not only expand our capabilities but also enable us to be more flexible and better serve our customers by reducing turnaround times.”

Vallair's NDT capability will comprise eddy current inspections, ultrasonics inspections as well as penetrant testing and will be overseen by Renaud Chastel, NDT manager for Vallair. Renaud recently joined Vallair to head up the programme and has accrued more than 10 years' NDT experience in companies all around the world including ATR, Airbus and most recently G2 Metric.

“Building the NDT department is a great challenge for me, and it will enable Vallair to be more efficient and responsive to the requirements of its customers,” explains Chastel. “NDT is a guarantee of quality and safety, so it is reassuring for the customer to know that Vallair is able to offer the complete scope of the treatment for any damage assessment or structural diagnosis. Thanks to the excellent work of our Quality department, we received a D1 Rating in our MOE for NDT at the end of June enabling us to perform varied inspections. The MRO world is evolving and new challenges await us all. Vallair is well prepared to meet the opportunities that lie ahead.”